Hauv kev lag luam ntawv, cov qauv fiber yog ib qho ntawm cov yam tseem ceeb uas txiav txim siab txog cov yam ntxwv ntawm cov pulp thiab qhov zoo ntawm daim ntawv kawg. Cov qauv fiber suav nrog qhov ntev nruab nrab ntawm cov fiber, qhov sib piv ntawm cov tuab ntawm phab ntsa fiber rau txoj kab uas hla ntawm cov cell (hu ua qhov sib piv ntawm phab ntsa mus rau qhov), thiab qhov ntau ntawm cov heterocytes tsis yog fibrous thiab cov fiber bundles hauv cov pulp. Cov yam no cuam tshuam nrog ib leeg, thiab ua ke cuam tshuam rau lub zog sib txuas ntawm cov pulp, kev ua haujlwm ntawm kev qhuav dej, kev ua haujlwm theej, nrog rau lub zog, kev tawv thiab qhov zoo ntawm daim ntawv.

1) Qhov nruab nrab ntawm cov fiber ntev

Qhov nruab nrab ntev ntawm cov fibers yog ib qho ntawm cov cim qhia tseem ceeb ntawm qhov zoo ntawm cov pulp. Cov fibers ntev dua tsim cov saw hlau ntev dua hauv cov pulp, uas pab txhim kho lub zog sib txuas thiab cov khoom tensile ntawm daim ntawv. Thaum qhov nruab nrab ntev ntawm cov fibers nce, tus lej ntawm cov ntsiab lus sib txuas ntawm cov fibers nce, tso cai rau daim ntawv kom zoo dua disperse kev ntxhov siab thaum raug sab nraud quab yuam, yog li txhim kho lub zog thiab toughness ntawm daim ntawv. Yog li ntawd, kev siv cov fibers ntev dua, xws li spruce coniferous pulp lossis paj rwb thiab linen pulp, tuaj yeem tsim lub zog siab dua, toughness zoo dua ntawm daim ntawv, cov ntawv no zoo dua rau kev siv hauv qhov xav tau cov khoom lub cev siab dua ntawm lub sijhawm, xws li cov ntaub ntawv ntim khoom, ntawv luam ntawv thiab lwm yam.

2) Qhov piv ntawm cov phab ntsa fiber cell thickness rau lub cell cavity diameter (phab ntsa-rau-cavity ratio)

Qhov piv ntawm phab ntsa mus rau qhov chaw yog lwm qhov tseem ceeb uas cuam tshuam rau cov khoom ntawm lub pulp. Qhov piv ntawm phab ntsa mus rau qhov chaw qis dua txhais tau tias phab ntsa ntawm lub cell fiber yog nyias thiab qhov chaw ntawm lub cell loj dua, yog li cov fibers hauv cov txheej txheem pulping thiab papermaking yooj yim dua los nqus dej thiab mos, ua rau kev ua kom zoo ntawm cov fibers, kev tawg thiab kev sib txuas. Tib lub sijhawm, cov fibers nyias-phab ntsa muab kev ywj pheej zoo dua thiab kev quav thaum tsim daim ntawv, ua rau daim ntawv tsim nyog dua rau kev ua cov txheej txheem nyuaj thiab tsim cov txheej txheem. Qhov sib piv, cov fibers nrog cov piv ntawm phab ntsa mus rau qhov chaw siab tuaj yeem ua rau daim ntawv tawv dhau, tawg yooj yim, uas tsis zoo rau kev ua thiab siv tom qab.

3) Cov ntsiab lus ntawm cov heterocytes uas tsis yog fibrous thiab cov fiber bundles

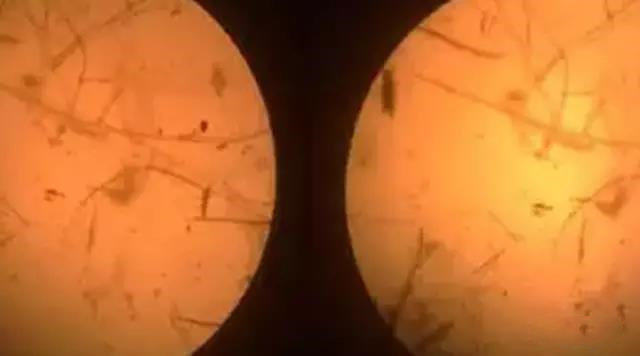

Cov hlwb tsis yog fibrous thiab cov fiber bundles hauv lub pulp yog cov yam tsis zoo uas cuam tshuam rau qhov zoo ntawm daim ntawv. Cov impurities no yuav tsis tsuas yog txo qhov purity thiab uniformity ntawm lub pulp, tab sis kuj tseem nyob rau hauv cov txheej txheem ua ntawv los tsim cov pob caus thiab qhov tsis zoo, cuam tshuam rau qhov du thiab lub zog ntawm daim ntawv. Cov heterocytes tsis yog fibrous yuav pib los ntawm cov khoom tsis yog fibrous xws li tawv ntoo, resin thiab cov pos hniav hauv cov khoom siv raw, thaum cov fiber bundles yog cov fiber aggregates tsim los ntawm qhov tsis ua tiav ntawm cov khoom siv raw kom dissociate txaus thaum lub sijhawm npaj. Yog li ntawd, cov impurities no yuav tsum tau tshem tawm ntau li ntau tau thaum lub sijhawm pulping kom txhim kho qhov zoo ntawm lub pulp thiab cov ntawv tawm.

Lub sijhawm tshaj tawm: Cuaj hlis-28-2024